Key Takeaways

- A shift towards green steel production in Pennsylvania's Mon Valley could revitalize the region's declining steel industry and boost the local economy.

- Green steel involves using hydrogen generated from renewable energy sources to manufacture steel, coupled with a renewably-powered electric arc furnace.

- The transition to green steel could increase jobs in the region by 27% to 43% by 2031, while sticking to the current trajectory could result in a 30% decrease in jobs.

- The development of green steel faces challenges, including the need for a more developed renewable energy infrastructure in Pennsylvania.

- The Mon Valley has untapped wind energy potential, which, if harnessed, could contribute to the region's green energy economy.

- Countries worldwide are pursuing green steel production to achieve net-zero emissions, with the European Union leading the way.

Pennsylvania’s Mon Valley, once a hub of American steel production, has seen a steady decline in steel-related employment over the past several decades.

However, a new study by the Ohio River Valley Institute posits that a transition to green steel could revitalize the industry and the local economy.

The region’s trained workforce, existing steelmaking infrastructure, abundant water resources, and untapped wind energy potential could pave the way for the next generation of American steelmaking.

Traditional steelmaking processes, which are heavily reliant on metallurgical coal, contribute significantly to global carbon emissions.

To combat this, the industry has seen a gradual shift towards recycling steel scrap in an electric arc furnace, a process that uses hydrogen instead of coke.

This not only reduces labor but also cuts down on emissions and energy usage.

The Ohio River Valley Institute’s study suggests that the move towards green steel could increase jobs in the region by 27% to 43% by 2031.

Meanwhile, if the industry sticks to its current trajectory, job numbers could fall by 30% in the same timeframe.

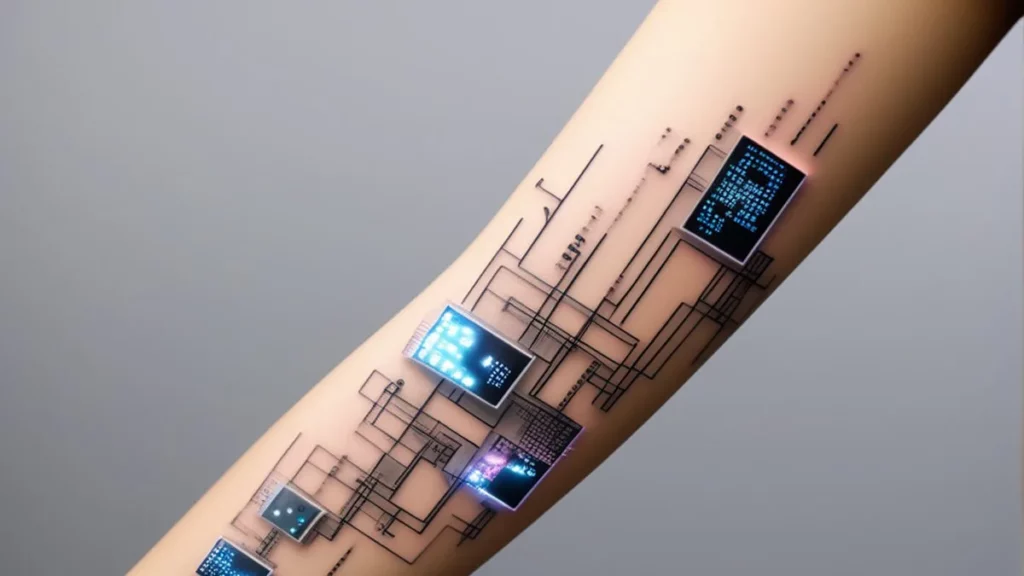

The Green Steel Revolution

The green steel revolution involves using hydrogen generated with renewable energy to manufacture steel.

This process, coupled with a renewably-powered electric arc furnace, is seen as the most viable near-term option for achieving zero-emission primary steel production.

This transition would not be without its challenges, particularly in light of Pennsylvania’s relatively underdeveloped renewable energy infrastructure.

However, the authors of the report believe that committing to green steel could also stimulate the development of a regional green energy economy.

The Mon Valley region has significant wind energy potential, though little of this has been tapped into.

Federal subsidies and tax breaks could give clean energy developers a boost, and the Biden administration has already shown support for green steel through various grant programs and tax credits.

The Ohio River Valley Institute’s study suggests that the move towards green steel could increase jobs in the region by 27% to 43% by 2031.

The Global Race for Green Steel

The push for green steel isn’t just a domestic matter. Countries worldwide are striving to achieve net-zero emissions, and many are already exploring green steel production.

Notably, the European Union is ahead of the curve, with green steel projects already underway in Sweden, Germany, and Spain.

However, U.S. companies are catching up. Boston Metal, for instance, is working on an oxide electrolysis model that eliminates the need for coal in the steelmaking process.

This model creates a chemical reaction that simulates the conversion of iron ore into steel. Boston Metal is currently in the process of licensing this process to steel manufacturers, expecting to see the first adopter by 2026.

A New Dawn for the Rust Belt

If the Mon Valley can successfully transition to green steel production, it could not only meet the demands of an increasingly eco-conscious global market but also revive a declining regional economy.

The implementation of green steel processes could also improve air quality and substantially reduce the region’s carbon footprint.

The major steel producer in the region, U.S. Steel, has signaled a commitment to decarbonization, though it has yet to commit to new local investments.

However, the changing industry landscape and the potential economic and environmental benefits of transitioning to green steel might serve as compelling reasons for them to invest in this area.

The potential of green steel could mark a new chapter for the Rust Belt, reinventing an industry that was once the lifeblood of the region and placing it at the forefront of sustainable innovation.